Research Interests

Did you know that there's more solar power hitting the Earth every hour than the global annual power consumption? Clearly, there's no dearth of solar energy resource in the world. The only challenge is: How do we develop technologies and systems that can effectively utilize this resource? I am interested in developing ways to efficiently harness solar energy and manage incoming solar radiation for diverse applications. My research interests can be broadly classifed as (with some obvious overlaps):- Heat Transfer: Solar thermal systems, Thermal radiation transfer, Radiative cooling, Phase change thermal systems, Geoengineering

- Light Transfer: Photoelectrochemistry, Photonics, Plasmonics, Indoor Lighting

- Optical Characterization Techniques: Spectrophotometry, X-ray Tomography, Photography

Publications

- Yalcin, R.A., McNeil, P.E., Bhanawat, A., Martinez, R., Kashanchi, G.N., Tolbert, S.H., Dunn, B.S. and Pilon, L., 2025. Dependent scattering and fractal microstructure determine the transparency of aerogel monoliths. APL Photonics, 10(4), pp. 046103

- Bhanawat, A., Martinez, R., Yalcin, R.A., Lee, T. and Pilon, L., 2024. Dependent scattering and plasmon coupling in concentrated suspensions of optically hard nanoparticles. Applied Physics Letters, 125(2), 021106

- Martinez, R., Bhanawat, A., Yalcin R.A., and Pilon, L., 2024. Rigorous accounting for dependent scattering in thick and concentrated nanoemulsions. The Journal of Physical Chemistry C, 128(15), pp.6419-6430

- Bhanawat, A., Yalcin R.A., Martinez R., and Pilon, L., Critical review and experimental validation of radiative transfer models for semitransparent media containing large gas bubbles Journal of Quantitative Spectroscopy and Radiation Transfer, vol. 311, pp. 108781

- Bhanawat, A. and Pilon, L., Light transfer through bubble-filled electrolyte for solar water splitting Sustainable Energy & Fuels vol. 7, no. 2, pp. 448–460, 2023

- Bhanawat, A., Zhu, K. and Pilon, L., How do bubbles affect light absorption in photoelectrodes for solar water splitting? Sustainable Energy & Fuels vol. 6, no. 3, pp. 910–924, 2022

- Yadav, M.K., Punetha, M., Bhanawat, A., Khandekar, S. and Sharma, P.K., Steam Condensation Heat Transfer During Initial Blow-Down Period of a Severe Nuclear Accident. Journal of Nuclear Engineering and Radiation Science, vol. 6, no. 4, 2020.

- Bhanawat, A., Yadav, M.K., Punetha, M., Khandekar, S. and Sharma, P.K., Effect of Surface Inclination on Filmwise Condensation Heat Transfer During Flow of Steam–Air Mixtures. Journal of Thermal Science and Engineering Applications , vol. 12, no. 4, p.041028, 2020

- Yadav, M.K., Punetha, M., Bhanawat, A., Khandekar, S., Muralidhar, K, Measurement of Condensation Heat Transfer. In: Drop Dynamics and Dropwise Condensation on Textured Surfaces. Mechanical Engineering Series. Springer, Cham., 2020

- Bhanawat, A., Yadav, M.K., Punetha, M. and Khandekar, S., Effect of surface inclination on film condensation heat transfer in the presence of air. In The Proceedings of the International Conference on Nuclear Engineering (ICONE) 2019.27 (p. 2133), The Japan Society of Mechanical Engineers, 2019.

- Punetha, M., Yadav, M.K., Bhanawat, A. and Khandekar, S., Steam condensation heat transfer inside reactor containment during the initial transient of a severe accident. In The Proceedings of the International Conference on Nuclear Engineering (ICONE) 2019.27 (p. 2166), The Japan Society of Mechanical Engineers, 2019.

M.TECH PROJECTS

Mentored by Prof. Sameer Khandekar, Phase Change Thermal Systems Laboratory, Department of Mechanical Engineering, IIT Kanpur

(May'18- Present)

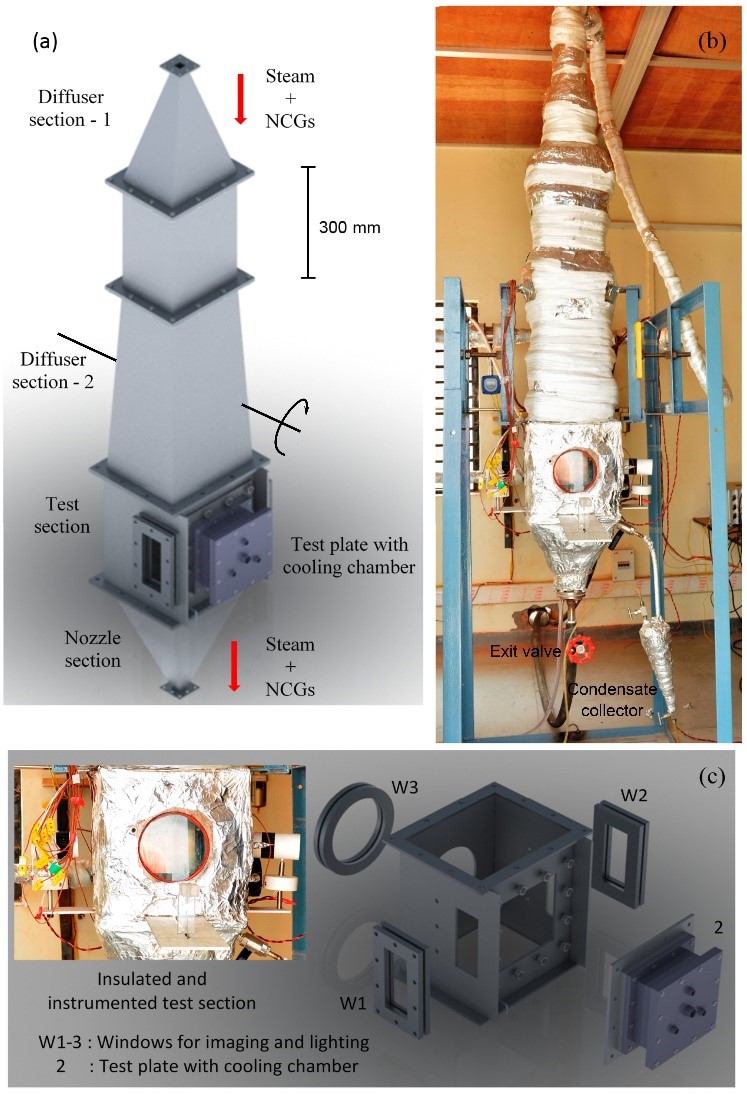

Steam condensation studies in the presence of non-condensable gases (NCG) for nuclear containment cooling

Objective: To experimentally study steam condensation heat transfer in the presence of non-condensable gases

Objective: To experimentally study steam condensation heat transfer in the presence of non-condensable gases

Motivation: In the event of a loss of coolant accident (LOCA) in a nuclear power plant, a lot of steam and hydrogen enter into the containment, which may lead to explosion, jeopardising the safety of the plant and plant workers. To prevent this, steam condensation should take place on the containment walls to remove the heat and relieve the pressure. This condensation is in the presence of non-condensable gases like Hydrogen and air.

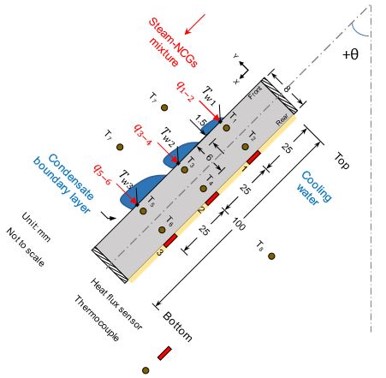

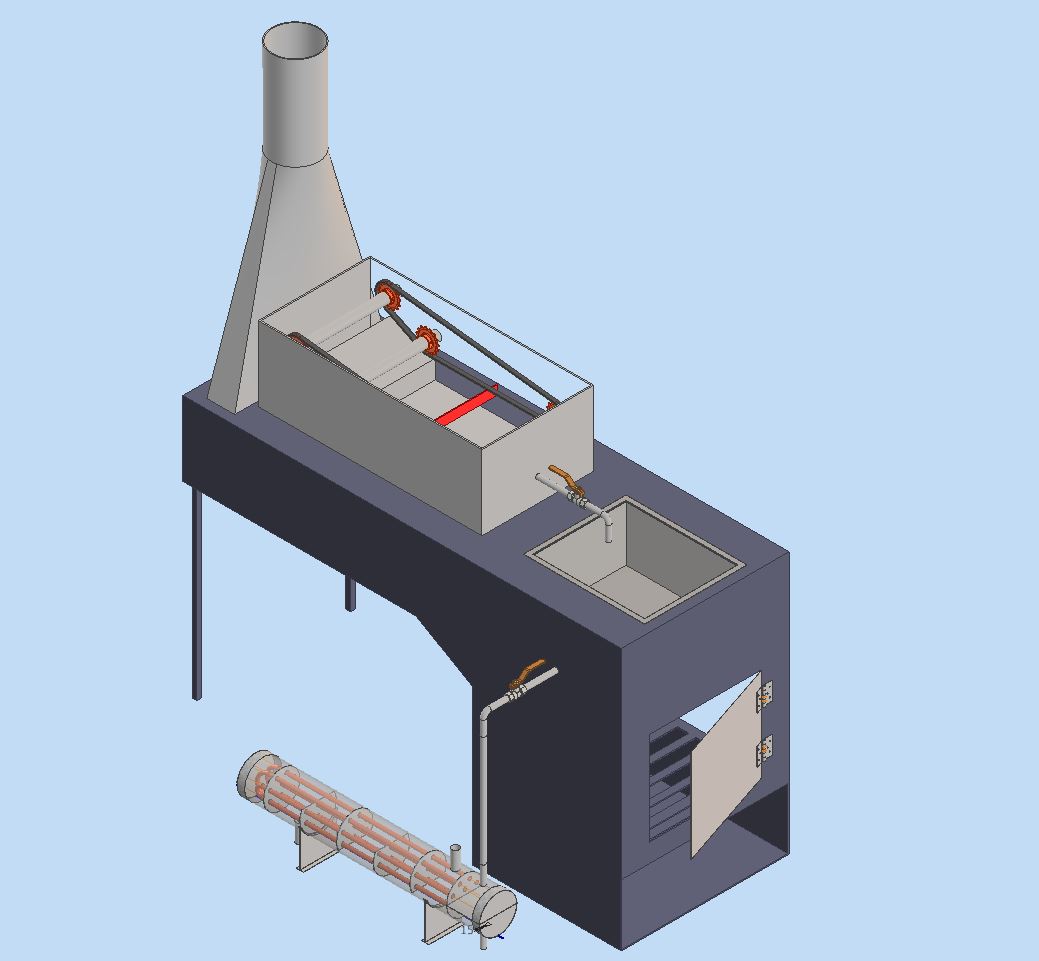

Description: A large-scale experimental facility (shown on the right) has been developed in-house as a part of Board of Research in Nuclear Sciences (BRNS)-sponsored research project, led by doctoral scholar Mr. Mahesh Kumar Yadav. Experiments were performed for studying heat transfer during film-wise condensation of steam on a test plate for different parameters like bulk pressure, NCG mass fraction, wall subcooling, plate inclination angle etc. Helium was used as a substitute for Hydrogen, considering the explosive nature of the latter. An online mass spectrometer was used to determine the composition of bulk mixture of air, steam and Helium.

The work has has been presented in the 27th International Conference on Nuclear Engineering (Japan, May 19-24, 2019) orally and via a poster. Its details are:

- Bhanawat A., Yadav M. K., Punetha M., Khandekar S., "Effect of surface inclination on film condensation heat transfer in the presence of air"

In addition, the research findings have also been submitted in the form of two journal papers, the details of which are as follows:

- Bhanawat A., Yadav M. K., Punetha M., Khandekar S., "Effect of Surface Inclination on Filmwise Condensation Heat Transfer during Flow of Steam-Air Mixtures", ASME Journal of Thermal Science and Engineering Applications (submitted)

- Punetha M., Yadav M. K., Bhanawat A., Khandekar S., "Steam Condensation Heat Transfer during Initial Blow-down Period of a Severe Nuclear Accident", ASME Journal of Nuclear Engineering and Radiation Science (submitted)

Effect of Inclination angle of the test plate on dropwise condensation of steam on the plate

Objective: To experimentally study the effect of test plate inclination angle on dropwise condensation of steam on the plate

Objective: To experimentally study the effect of test plate inclination angle on dropwise condensation of steam on the plate

Motivation: Dropwise condensation is an attractive mode of heat transfer because of its significantly higher heat transfer coefficient as compared to filmwise mode for the same temperature difference. It is also useful in many other applications, such as water distillation, uranium enrichment etc. One of the methods of solar water distillation employs water vapour condensing on inclined plates, the heat transfer in which is not very well documented.

Description:

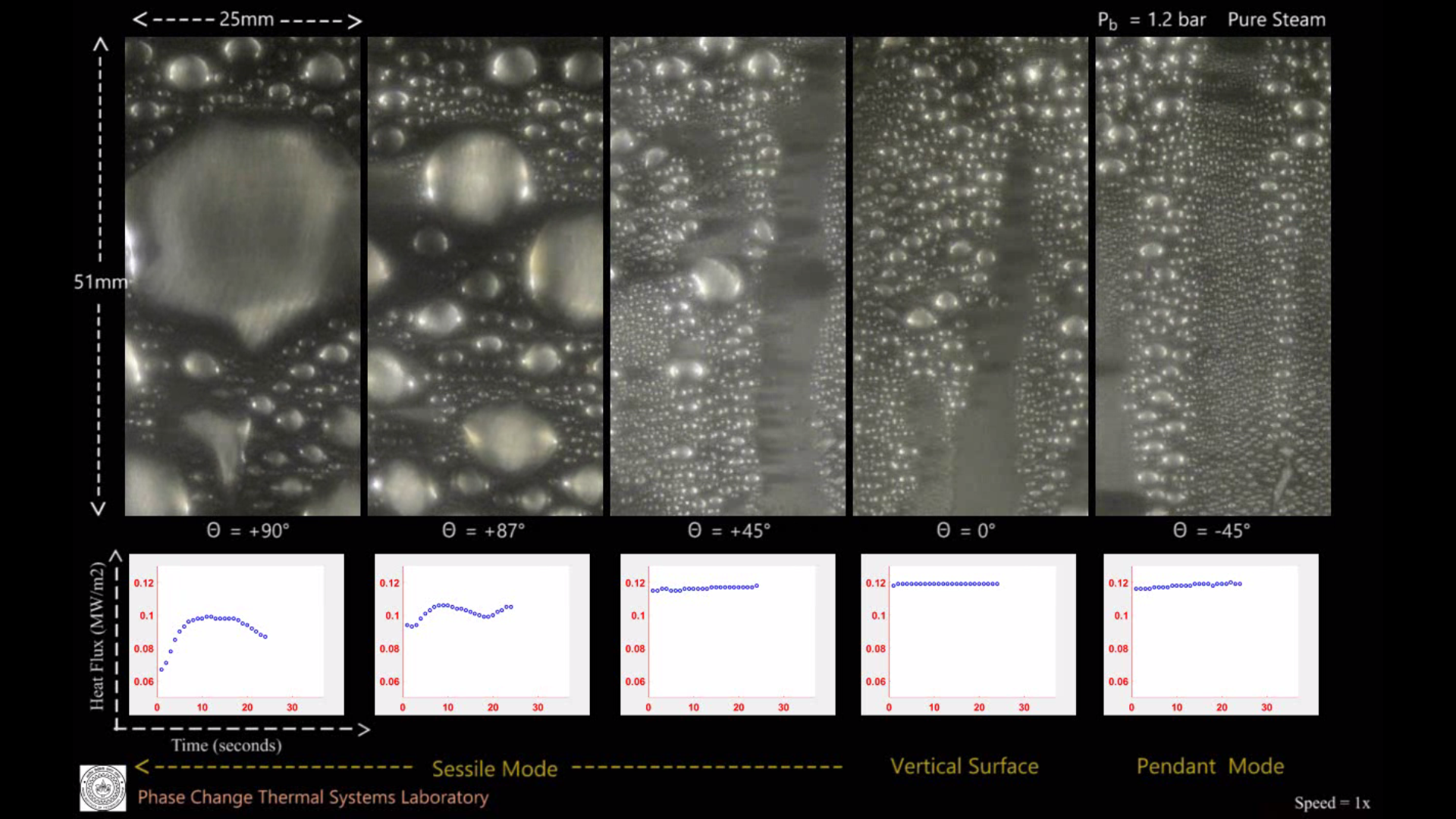

The same experimental facility, as described in the previous project, is used to perform experiments for dropwise condensation for different plate inclination angles and wall subcooling while keeping other parameters constant. The plate inclination angle Θ (shown on the right) varies from -90°(pendant mode on horizontal plate) to +90°(sessile mode on horizontal plate) in increments of ~20°, in order to fully capture the effect. These inclinations were possible due to the impressive design of the experimental setup which allows 180° rotation in either direction.

The visual data recorded with the help of a digital camera has been compiled for some specific angles in a video for comparison, a screenshot of which is shown below. The video considers one cycle (drop formation to coalescence to sweep) for +90° and compares the visual data for the same time for different inclination angles. The corresponding average heat flux, varying in real time, is shown below each of the visual data for comparison.

The research findings have been submitted in the form of a book chapter, the details of which are:

- Yadav M.K., Bhanawat A., Punetha M., Khandekar S., "Condensation Heat Transfer Measurement", Book Chapter (Submitted), Drop Dynamics and Dropwise Condensation on Textured Surfaces, Springer Mechanical Engineering Series, 2019-20

B.Tech Project: Design and fabrication of a sugarcane syrup making machine

Mentored by Prof. P. S. Ghoshdastidar, Department of Mechanical Engineering, IIT Kanpur(August'17-April'18)

Objective: To design and fabricate a semi-automatic machine that converts sugarcane juice into its syrup

Motivation: Farming is becoming increasingly non-remunerative. On the other hand, the food products made from farm produce are getting costlier. So, value addition to the farm produce seems to be a nice solution for farmers to be able to earn more and also provide them with the opportunity to enter new markets. This value addition in agricultural products can be in the form of breads, sausages, syrups etc.

Description: Sugarcane syrup making from juice involves mainly three processes: removing dissolved impurities, concentrating the juice and rapid cooling of hot juice (for better taste of syrup). We designed and fabricated this machine in the Central Workshop at IIT Kanpur, catering to each of these three processes. An innovative chain and sprocket mechanism with a skimmer attached to it continuously removes the scum from the surface of the juice as it is heated. The juice is then transferred to the evaporating pan where it is vigorously boiled and concentrated, using waste sugarcane bagasse as fuel. Finally, the hot syrup is passed through the tubes of a shell and tube heat exchanger (designed and fabricated in-house) with water flowing in the shell to quickly cool the syrup. This machine can be extended for making syrup of sweet sorghum crop, which is rather less-explored and can help farmers earn a lot because of the medicinal properties of the syrup.